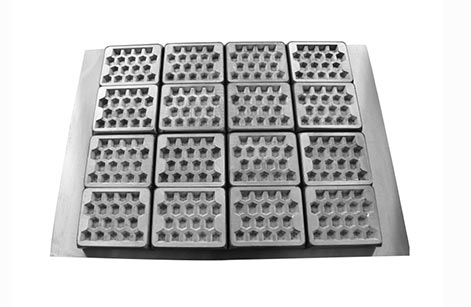

FORMING MOLD FEATURES

- The material of forming mold installation plate, pad high block, pressing frame, molding cavity, strip etc is aluminum, because aluminum has good thermal conductivity ,fast molding preheating, more conducive to forming products and make it integrity, reduce the heating time.

- Through the cavity cooling way to achieve the cooling effect, just let the cooling water through the cavity to achieve the cooling effect of the cavity, this cooling mode is much better than the cooling plate, can maintain the demoulding temperature.

- The forming mould is equipped with a waterproof O-ring to prevent the cooling water leaks out at the connection.

- Nylon faucet used for stretching head when forming, this material is light and surface finish is easy to process.

- Installation plate, pad high block, pressing frame, strip and so on have been sandblasted on the surface which can spray off the small scratches on the surface and change the surface color, so that the whole mold looks small color difference, more beautiful, also can prevent aluminum rust.

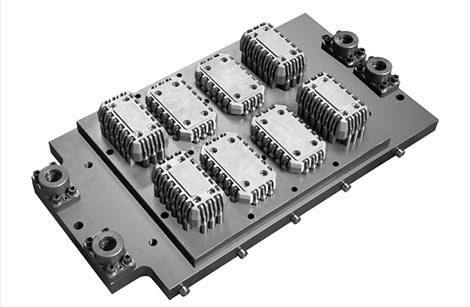

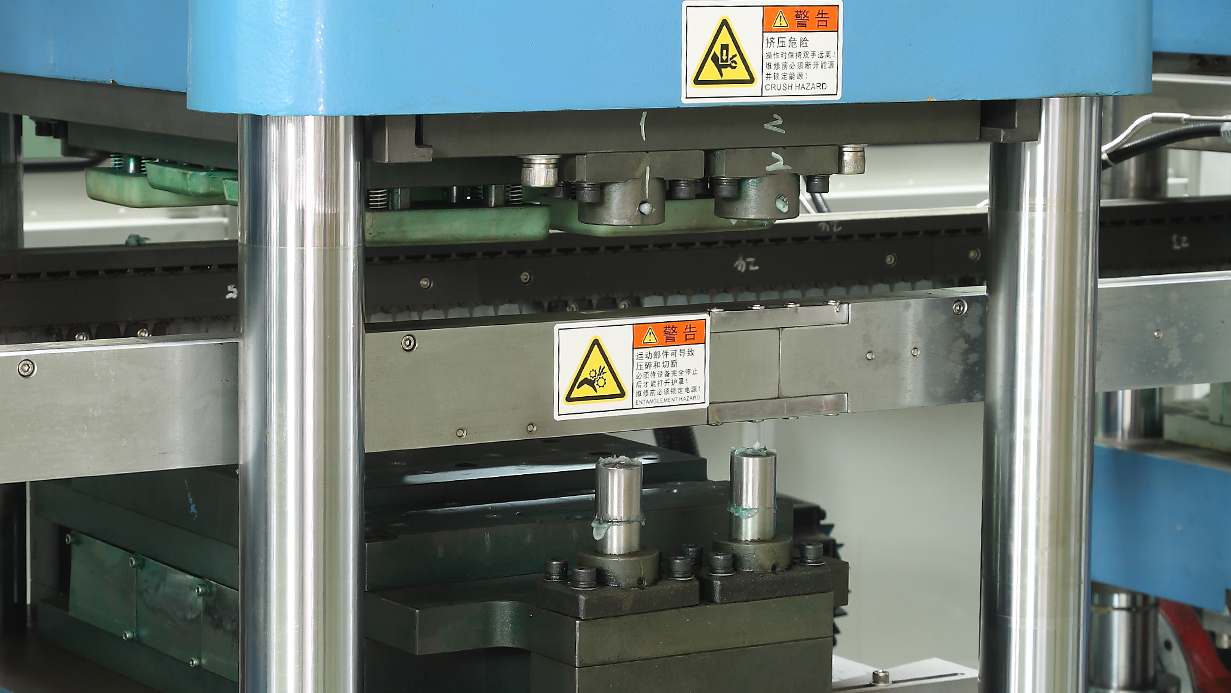

PUNCHING MOLD FEATURES

- The guide sleeve material of punching die guide column is GCr15 steel, with high hardness and wear resistance, durable and good thermal processing.

- Perforating die mounting plate, fixed plate, pad high block, knife plate and so on all use 45# steel which is not easy to deformation to ensure small deformation of punching mould.

- Each part has been phosphating treatment to prevent rust.

- It is equipped with holed waste cover to prevent holed waste flying out and affecting cleanliness.

CUTTING MOLD FEATURES

- Mounting plate, pad high block, pad, fixed block and other materials are made of aluminum, because it is light and good thermal conductivity, which is conducive to the preheating of the blanking knife and convenient to cut off products.

- The material used is stainless steel, not easy to rust, and the use of laser cutting processing, cutting speed, high efficiency, good quality.

- The punching die is processed by grinding machine to ensure that the sheet is cut off completely and the cutting is more fine.

- Punching knife installation plate, punching cutting plate ,pad high block, punching cutting die installation plate and pad high block are also processed by surface sandblasting treatment, more beautiful and also can prevent aluminum embroidery.

- Punching cutting knife is used in active mode, convenient to adjust the width of punching.

- The cutter has automatic heating function, the heated cutter can cut the product better.

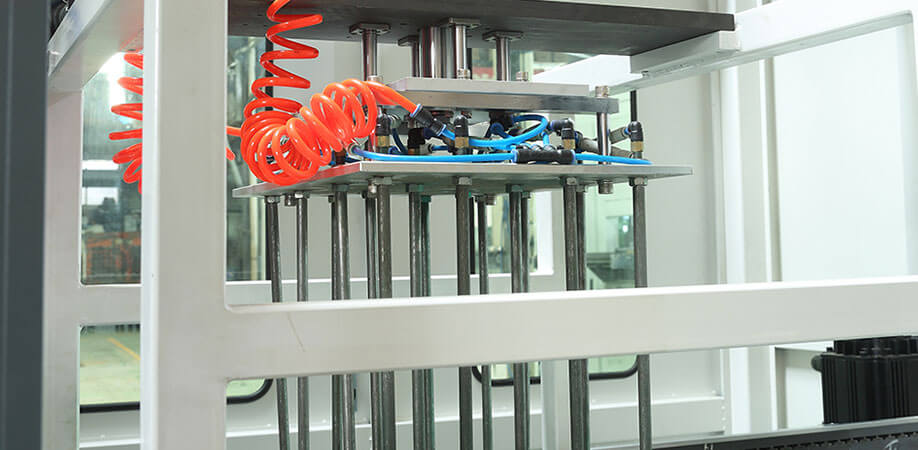

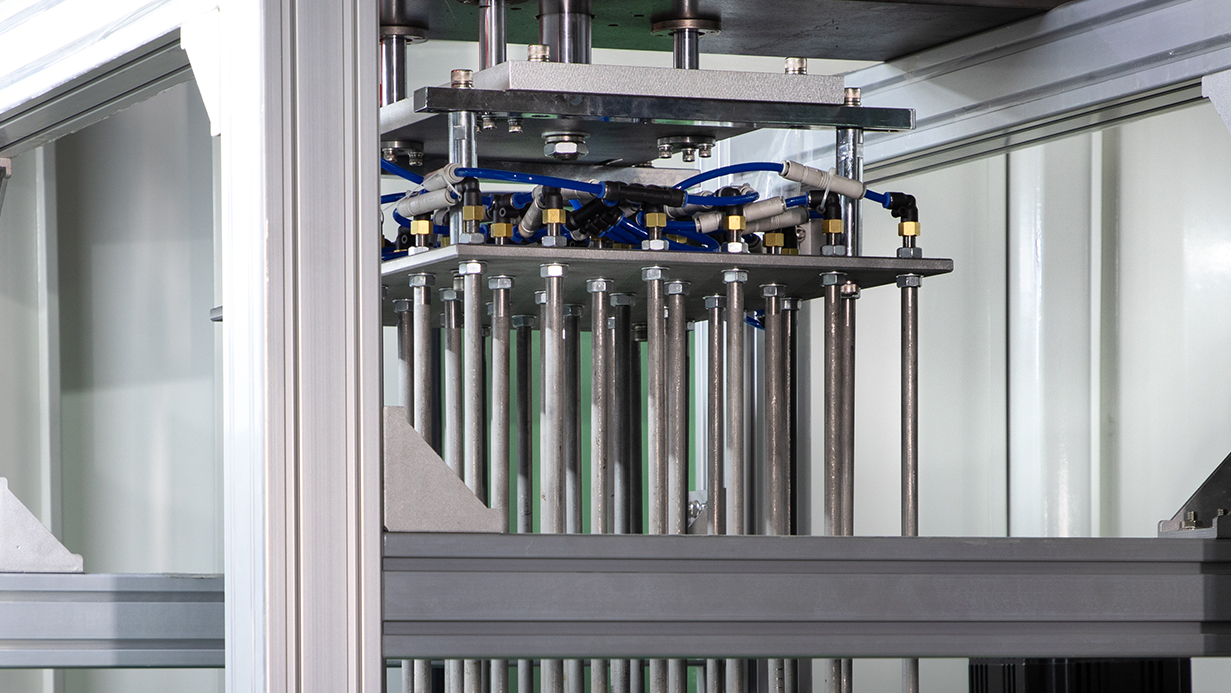

STACKED MOLD FEATURES

- Stacking suction rod fixing plate is made of aluminum, which is light and does not increase stacking burden.

- The surface after sandblasting treatment, can change the surface color so that the whole mold looks small color difference and also can prevent aluminum rust.

- Stack suction rod is made of 304 stainless steel, which is not easy to rust.

CUP MACHINE MOLD FEATURES

- Stretching head: we use PA66,PQM, inlaid metal etc..These materials are more durable and wear-resistant.

- The cutting edge adopts Cr12Mov,SKD11,DC53 and other materials, after rough turning, heat treatment, high precision grinding and other processes, so that the upper edge and the lower edge are perfectly matched, and the cutting is more precise and fine.

- Cup gallbladder material is aluminum alloy, relatively light, good thermal conductivity, fast preheating, easy demoulding.

- The head of the top cup is made of aluminum alloy, brass and other materials, and the logo can be customized according to customer needs.

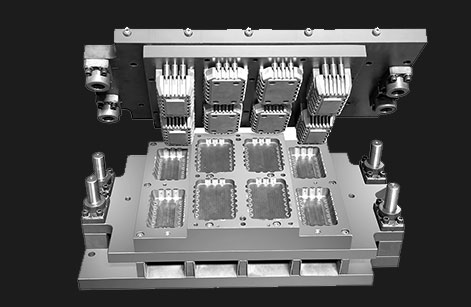

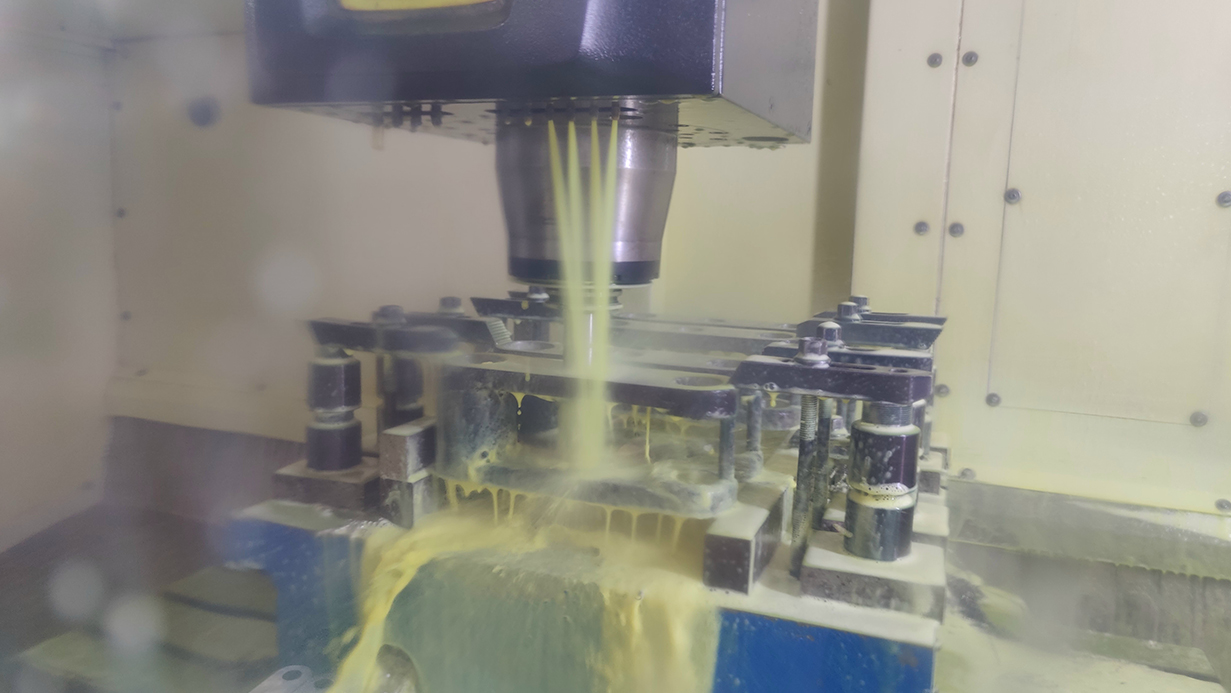

THE INTERNAL STRUCTURE, RAW MATERIALS AND PROCESSING TECHNOLOGY OF THE FORMING MOLD

- Mounting plate material for forming upper mold: aluminum. It is processed and shaped by a machining center. Fitter chamfering and drilling. Surface sandblasting

- Material of forming stretch board: 45#. Processed by a grinder. The machining center processes forming fitter chamfering, drilling and tapping. Surface phosphate treatment

- Forming upper mold block 2 material: aluminum. It is processed and shaped by a machining center. Fitter chamfering and drilling. Surface sandblasting

- Material of forming stretch rod: 45#. Processed by a lathe. The shaft is chrome-plated by the grinder. Grinding machine processing. The fitter clears the burrs and drills holes.

- Forming upper mold block 1 material: aluminum. It is processed and shaped by a machining center. Fitter chamfering and drilling. Surface sandblasting

- Material of forming stretch head: Nylon. It is carved and processed by an engraving machine. The fitter is aware of burrs, drilling and tapping. Requires a smooth surface

- Molding material frame material: aluminum. It is processed and shaped by a machining center. Fitter chamfering and drilling. Outsourcing cold water hole processing. Surface sandblasting

- Material of molding cavity wall 2: aluminum. It is processed and shaped by a machining center. Fitter chamfering and drilling. Surface sandblasting

FORMING MOLD FEATURES

- The material of forming mold installation plate, pad high block, pressing frame, molding cavity, strip etc is aluminum, because aluminum has good thermal conductivity ,fast molding preheating, more conducive to forming products and make it integrity, reduce the heating time

- Through the cavity cooling way to achieve the cooling effect, just let the cooling water through the cavity to achieve the cooling effect of the cavity, this cooling mode is much better than the cooling plate, can maintain the demoulding temperature

- The forming mould is equipped with a waterproof O-ring to prevent the cooling water leaks out at the connection

- Nylon faucet used for stretching head when forming, this material is light and surface finish is easy to process

- Installation plate, pad high block, pressing frame, strip and so on have been sandblasted on the surface which can spray off the small scratches on the surface and change the surface color, so that the whole mold looks small color difference, more beautiful, also can prevent aluminum rust